Solutions

SMS’s 6IX Solution’s (Smart Industrial Transformation) contain 6 core components including, Sensors, Gateways, Monitoring, Alerts, Analytics, and Cloud. The combination of hardware, software, and service components have been tested and validated to meet almost all of our client’s needs. 6IX is delivered as industry or equipment solutions, such as 6IX for Robot Signature Analysis, Machine Tool Operation, Building Management, and Agriculture.

These pre-built 6IX solutions allow us to onboard clients quickly and efficiently, delivering a true time-to-value solution. Splunk’s Edge Hub device enables rapid deployment at the machine level, offering the ability to connect and analyze data from CNC machines and other tools that have historically been hard to reach. The Edge Hub can interface with existing machine controllers, deploy edge computing, and push machine performance and condition data into analytic platforms, such as Splunk Enterprise. It’s built in sensors provide additional context, such as environmental conditions, which can help correlate with machine issues. This capability is crucial and allows us to connect to more machines, capture more operational data, and deliver deeper insights into machine performance and maintenance.

Partner Solutions

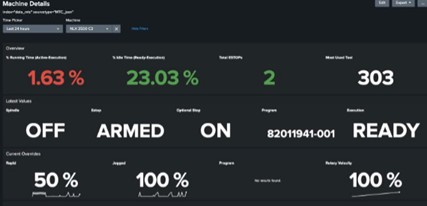

Machine Tool Operations (MTO)

Improve Production Visibility

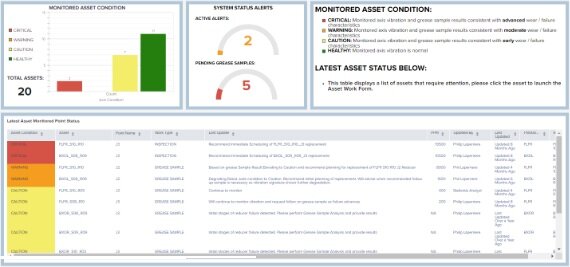

Dashboards and KPI’s provide advanced insights to improve decision making such as production scheduling, resource allocation, and process improvements.

Increase Quality

Real-time data monitoring allows for the early detection of deviations from quality standards, enabling immediate corrective actions.

Reduce Downtime

Avoid unplanned downtime with real-time tracking that provides prompt insights into gateways, sensors, and connectivity status.

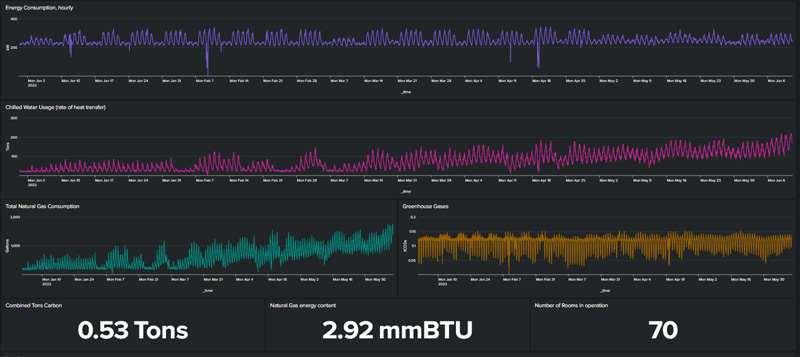

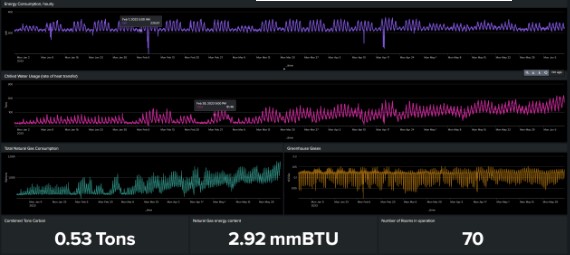

Building Management Systems (BMS)

Energy Efficiency

By tracking energy use, building managers can identify areas for improvement, leading to reduced energy costs.

Improved Indoor Comfort and Air Quality

Monitoring HVAC and AHUs ensures optimal temperature and humidity levels, improving occupant comfort.

Reduce Downtime

Early detection of problems reduces the likelihood of costly emergency repairs, extend the equipment’s life, and improves planning.

Agriculture Monitoring (AgM)

Improve Production Visibility

Dashboards and KPI’s provide advanced insights to improve decision making such as production scheduling, resource allocation, and process improvements.

Increase Quality

Real-time data monitoring allows for the early detection of deviations from quality standards, enabling immediate corrective actions.

Reduce Downtime

Avoid unplanned downtime with real-time tracking that provides prompt insights into gateways, sensors, and connectivity status.

6IX for Fast Rotating Equipment (FRE)

Reduce Downtime

Avoid unplanned downtime with real-time tracking that provides prompt insights into gateways, sensors, and connectivity status.

Increase Quality

Real-time data monitoring allows for the early detection of deviations from quality standards, enabling immediate corrective actions.

Increased Safety

Identify hazardous conditions before they escalate into dangerous situations.

6IX for Convenience Store Monitoring (CSM)

Reduce Energy Costs

Energy is the 4th biggest cost driver of store operations for C-stores, typically accounting for between 4% and 9% of in-store operating costs.

Improve Consumer Experience

With infinite choice available at a swipe or a click, customer loyalty is fickle. If your store is not comfortable, safe, clean or efficient, they will take their business elsewhere.

Reduce Operational Risks

Store assets can expose you and your customers health, information security, and compliance risks, through malfunctioning refrigeration, or through a security vulnerability in a connected device such as a sensor.