Partner Solutions

IoT-Enhanced Operational Efficiency

Lower Costs

Experience reduced equipment downtime and lower maintenance costs by optimizing maintenance schedules based on real-time data.

Reduce Incidents

Achieve fewer security incidents and unauthorized access attempts with advanced anomaly detection and security features. Use real-time alerts and automated responses to enable swift action.

Streamline Compliance

Streamline compliance monitoring and reporting processes to reduce compliance-related costs and efforts. Use automated compliance checks and customizable reporting capabilities to facilitate compliance assessments.

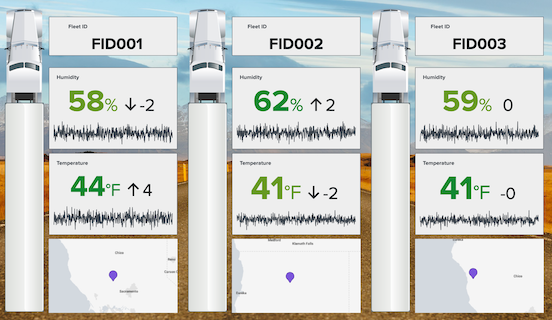

Fleet Insights: Logistics and Commodity Transport

Maximize Fleet Efficiency & Uptime

Optimize fleet performance and reduce downtime with real-time tracking, advanced analytics, and predictive maintenance. Our solution ensures your fleet operates at peak efficiency, minimizing costly disruptions.

Protect Cargo & Enhance Driver safety

Safeguard your cargo and prioritize driver safety with real-time monitoring and alerts. Our platform helps maintain optimal conditions for your commodities while promoting safe driving practices.

Data-driven Insights for Decisions

Gain actionable insights from customizable dashboards and comprehensive reports. Our solution empowers you to make informed, data-driven decisions that drive your fleet's success.

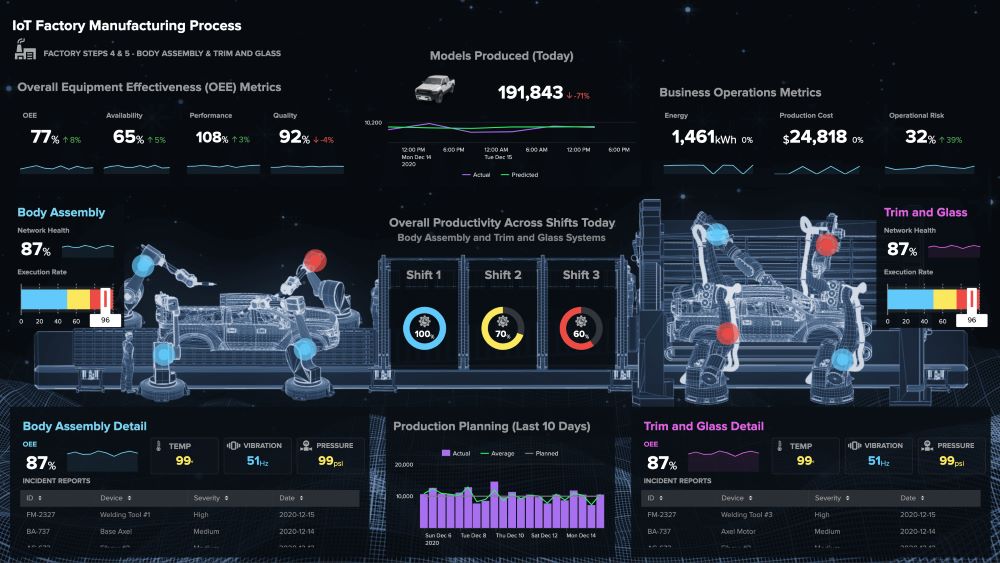

Manufacturing Anomaly Detection

Smart & Sustainable Manufacturing

Achieve sustainability goals

Increase energy efficiency and see cost savings with Splunk Edge Hub’s alignment of sustainability targets.

Inform business decisions

Enhance decision-making capabilities through a holistic view, combining Splunk Edge Hub data with more comprehensive business insights within Splunk’s Data Platform.

Optimize production performance

Elevate production reliability and efficiency with Splunk Edge Hub’s predictive insights into every aspect of your manufacturing processes.

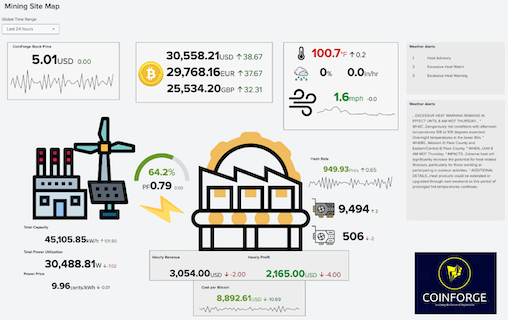

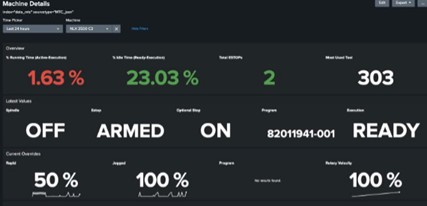

Machine Tool Operations (MTO)

Improve Production Visibility

Dashboards and KPI’s provide advanced insights to improve decision making such as production scheduling, resource allocation, and process improvements.

Increase Quality

Real-time data monitoring allows for the early detection of deviations from quality standards, enabling immediate corrective actions.

Reduce Downtime

Avoid unplanned downtime with real-time tracking that provides prompt insights into gateways, sensors, and connectivity status.

Manufacturing Management

Predictive Maintenance

Monitor Assets

Monitor your assets in real time, allowing your organization to address any issues detected before they result in downtime.

Gain Visibility

Gain a greater level of visibility into all of your infrastructure and assets, greatly improving the services offered to your customers.

Create Internal Resources

Create knowledge objects based on collected data to perform remote diagnostics, achieving a much higher time to resolution and reducing the cost of having to send engineers on site.

Manufacturing Monitoring

Gain Visibility

Gain a much greater level of visibility into all your infrastructure and assets, greatly improving the services offered to your customers.

Reduce Costs

Find the most efficient working processes with increased monitoring, whether by finding ways to improve fuel efficiency, working practice or through the implementation of predictive maintenance.

Encourage Better Working Practices

Ensure the best working practices are being adhered to and the most efficient working methods are being implemented with the increased visibility offered by streaming IoT data via Splunk Edge Hub.